In the realm of machining, achieving efficient and precise threading of through holes in tough materials has long been a challenge for manufacturers. Enter Speedy’s HSSE machine tap—a game-changing solution engineered to redefine industry standards and meet the demands of the most exacting machining tasks.

Speedy’s HSSE machine tap is meticulously designed for the efficient and accurate threading of through holes in a variety of tough materials. Whether you’re working with high-strength alloy steels or challenging titanium alloys, this tap delivers consistent, high-precision results, minimizing the risk of part rejection due to threading inaccuracies and ultimately saving your business valuable time and costs.

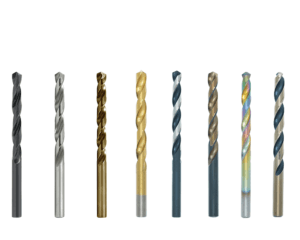

Compliant with DIN371 standards, our DIN371 compliant tap undergoes rigorous quality control at every stage of production. Its high-performance TiCN (Titanium Carbonitride) coating is the key to its superior performance. This advanced TiCN coated tap offers exceptional wear resistance, significantly extending the tool’s lifespan and reducing downtime caused by frequent tap replacements. Additionally, the excellent heat protection provided by the TiCN coating ensures stable machining even under high-temperature conditions, maintaining the integrity and precision of your threads.

Crafted from high-speed steel with added cobalt (HSSE), this high-speed steel cobalt tap offers optimal hardness and performance in demanding machining environments. The unique material composition provides the perfect balance of toughness and rigidity, allowing it to withstand high loads and speeds without compromising on accuracy or durability.

If you’re in search of a reliable, high-performing machine tap for tough material threading, Speedy’s HSSE machine tap is the ideal choice. Don’t miss out on the opportunity to enhance your operations—reach out to us today!

Call us now : +0086 13852960327

Keywords: