In the realm of metalworking and industrial drilling, the right tool can transform a challenging task into a seamless operation. The DIN345 HSS Morse Taper Shank Twist Drill Bit stands as a testament to engineering excellence, designed to meet the rigorous demands of professional drilling applications.

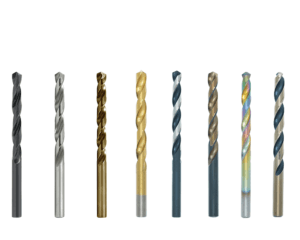

Crafted from high-speed steel (HSS), these drill bits offer exceptional durability and heat resistance, making them ideal for metal drills tasks. Unlike standard drill bits, HSS variants maintain their sharpness even when drilling through tough materials like steel, cast iron, and alloy metals. This resilience ensures consistent performance over extended use, reducing the need for frequent replacements and boosting productivity in workshops and manufacturing facilities.

The Morse taper shank is a defining feature that sets these drill bits apart. Following the DIN345 standard, the taper design creates a secure, self-locking connection with the drill chuck, eliminating slippage during high-torque drilling. This not only enhances safety but also ensures precise hole alignment, a critical factor in precision drilling projects where accuracy is non-negotiable. Whether you’re working on automotive parts, machinery components, or structural metal, the stable grip of the Morse taper shank minimizes errors and guarantees clean, uniform holes.

As a key player in the jobber drill category, the DIN345 HSS Morse Taper Shank Twist Drill Bit is engineered for versatility. It excels in both light-duty and heavy-duty drilling, adapting effortlessly to different metal thicknesses and hardness levels. From thin sheet metal to thick steel bars, this drill bit delivers consistent results, making it a go-to tool for professionals who handle diverse drilling tasks. Its ability to tackle various materials without compromising on speed or precision makes it an invaluable addition to any toolbox.

Compliance with the DIN345 standard is more than just a mark of quality—it’s a promise of compatibility and performance. This standard ensures that the drill bits meet strict dimensional and performance criteria, allowing them to integrate seamlessly with a wide range of drilling machines. Whether used in bench drills, pillar drills, or industrial drilling rigs, the HSS taper shank drill bits maintain their efficiency, reducing downtime and ensuring smooth workflow in any setting.

Durability is further enhanced by the drill bit’s twist design, which facilitates efficient chip removal. The flutes carry away debris from the drilling site, preventing clogging and reducing friction. This not only prolongs the life of the drill bit but also improves the quality of the hole, as fewer chips mean less heat buildup and less material distortion. For professionals working on high-precision projects, this feature is indispensable, as it ensures that each hole meets tight tolerances.

Investing in a HSS taper shank drill bit like the DIN345 model is a smart choice for businesses looking to optimize their drilling processes. Its combination of HSS construction, Morse taper shank, and adherence to industry standards translates to longer tool life, higher productivity, and superior results. Whether you’re a metalworking shop owner, a mechanical engineer, or a DIY enthusiast tackling heavy-duty metal projects, this drill bit delivers the reliability and performance you need.

In conclusion, the DIN345 HSS Morse Taper Shank Twist Drill Bit is a cornerstone of precision drilling in metalworking. It embodies the qualities that professionals demand: durability, accuracy, versatility, and compliance with industry standards. For anyone serious about achieving exceptional results in metal drilling, this drill bit is not just a tool—it’s a long-term investment in quality and efficiency.