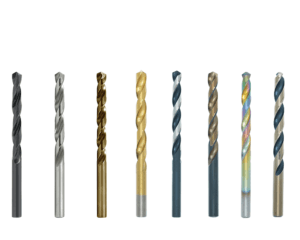

Removing spot welds is a common task in automotive repair and metalworking, essential for separating joined metal panels without causing damage to the underlying materials. A highly effective method for this process involves using HSS Spot Weld Drill Bits, typically available in 6mm and 8mm sizes. This is specially made, not for all drill bit manufacturers.

Understanding Spot Welds

Spot welding is a technique that fuses two or more metal sheets together at small, localized points using heat and pressure. This method is widely used in automotive manufacturing due to its efficiency and strength. However, when repairs or modifications are necessary, these welds must be carefully removed to maintain the integrity of the panels. Nowadays drill bit made in China is known for their durability and precision.

Tools for Spot Weld Removal

To remove spot welds effectively, specialized tools are recommended:

Spot Weld Cutters:

These function like small hole saws, cutting around the weld to separate the panels. They are particularly useful when the goal is to preserve the underlying panel.

HSS Spot Weld Drill Bits:

Designed specifically for spot weld removal, these drill bits allow for precise drilling that removes the weld with minimal damage to surrounding areas. It’s customized drill bit. Any length is available.

Procedure for Removing Spot Welds with HSS Drill Bits

- Identify Spot Welds: Locate all the spot welds on the panel that need to be separated.

- Center Punch: Use a center punch to create a small indentation on each spot weld. This step guides the drill bit and prevents it from wandering during drilling.

- Select Drill Bit Size: Choose between a 6mm or 8mm HSS Spot Weld Drill Bit based on the size of the weld.

- Drill the Weld: Align the drill bit with the punched mark and drill through the weld, taking care to penetrate only the top layer to avoid damaging the underlying panel.

- Separate Panels: After drilling all the spot welds, gently pry the panels apart using an appropriate tool.

Advantages of Using HSS Spot Weld Drill Bits

- Precision:

The pilot point design ensures accurate drilling without skidding, which is critical for maintaining panel integrity. - Efficiency:

These drill bits are specifically designed for spot weld removal, making the process quicker and more effective compared to other methods. - Versatility:

Suitable for use on hard steel and brass, they are ideal for auto body repair and restoration projects.

The HSS Spot Weld Drill combines precision, durability, and efficiency, making it an excellent choice for professionals in automotive repair and restoration. Its specialized design and quality construction ensure that spot welds are removed cleanly and efficiently, leaving the panels intact for further work. You can source it from drill bit suppliers, ensure that spot welds are removed cleanly and efficiently.

Keywords:

drill bit manufacturers