In professional drilling applications—from precision metal fabrication to industrial maintenance—tool performance directly impacts workflow efficiency and machining quality. The Spiral Groove Step Drill Bit Titanium Coating Round Shank emerges as a technical advancement in drilling tools, engineered to address the core pain points of professionals: multi-size compatibility, wear resistance, and consistent hole precision across diverse materials.

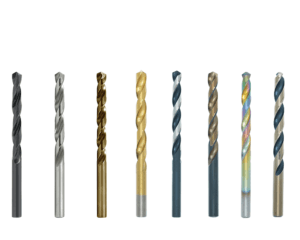

At the heart of its performance is the titanium coating—specifically a TiN (Titanium Nitride) layer, an industry-standard enhancement for cutting tools. This coating boosts surface hardness to 80 HRC, reducing friction during high-speed drilling (up to 3,000 RPM for non-ferrous metals) and minimizing heat accumulation. For professionals working with continuous production runs, this translates to a 30% longer tool lifespan compared to uncoated step drill bits, reducing downtime for tool replacement.

The round shank features a precision-machined 3-flat design (compliant with ISO 10893 standards), ensuring maximum torque transmission and chuck grip stability. This eliminates radial runout—a common issue with low-tolerance shanks that causes hole diameter deviations—and guarantees repeatable accuracy (±0.02mm) for critical applications like electrical panel installation or automotive component machining.

Complementing the shank design is the spiral groove (helix angle: 30°), optimized for chip evacuation efficiency. Unlike straight-flute step bits that trap debris, the spiral flute channels chips upward and away from the cutting zone, preventing clogging and surface marring. This is particularly critical when drilling thin-gauge sheet metal (0.5–3mm thickness) or soft plastics, where chip buildup can lead to material deformation or uneven hole edges.

As a professional step drill bit, it integrates 5–12 graduated hole sizes (depending on model) in a single tool, eliminating the need for tool changeovers in batch processing. It delivers burr-free machining across a range of substrates: aluminum alloys (6061-T6), mild steel (A36), hardwoods, and engineering plastics (ABS, PC). For metal drills specialists, this versatility reduces tool inventory costs while maintaining the high precision required for aerospace, electronics, and HVAC manufacturing.

In summary, this spiral groove step drill bit is not just a utility tool—it’s a precision-engineered solution that aligns with professional drilling demands. Its titanium coating, round shank stability, and spiral chip evacuation design make it indispensable for applications where consistency, durability, and efficiency are non-negotiable.