What Are Carbide Burr Bits?

Carbide rotary burrs are essential tools in metalworking, woodworking, and various industrial applications. They come in different flute styles, shapes, and materials, each suited for specific tasks. Among them, double-cut burrs are more widely used due to their efficiency and versatility.

While all carbide burrs are made from tungsten carbide, their raw materials can be either virgin carbide or recycled carbide. Virgin carbide is more expensive but offers superior quality, durability, and a smooth, polished finish. You should get to know in details when sourcing the rotary burr factory.

How Are Carbide Burr Bits Used?

Deburring – Removing sharp edges and excess material from metal, plastic, or wood.

Shaping & Carving – Engraving intricate details or refining workpieces.

Cutting & Hole Making – Enlarging holes or creating precise cuts.

Smoothing & Surface Finishing – Polishing and refining rough surfaces.

Weld Cleaning – Removing weld spatter and smoothing joints.

What Materials Can Carbide Burr Bits Work On?

Metals – Steel, aluminum, brass, copper, cast iron, and stainless steel.

Wood – Softwood, hardwood, and engineered wood.

Plastics & Fiberglass – Acrylic, PVC, composites, and resin-based materials.

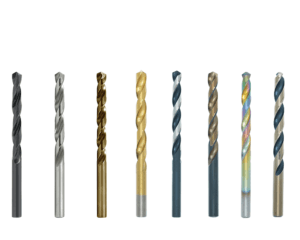

What Are the Different Types of Carbide Burr Bits?

Flute Types

- Single Cut – Ideal for fast material removal on harder metals. Produces long chips.

- Double Cut – Provides better control and smoother finishes, reducing vibration. This is a popular choice for wholesale rotary burr dealers due to its versatility.

Common Burr Shapes

Shape A – Cylindrical End Cut

Shape C – Cylindrical Ball Nose

Shape D – Ball Shape

Shape E – Oval Shape

Shape F – Flame Shape

Shape G – Pointed Tree Shape

Shape H – Tree Shape

Shape L – Ball Nose Cone

Shape M – Pointed Cone

Shape N – Inverted Cone

These carbide burr shapes are available from rotary burr manufacturers and can be purchased through wholesale rotary burr distributors. They serve various applications, whether you’re working on cutting tools for stone or in industrial settings that require precision.

Keywords:

rotary burr factory,wholesale rotary burr,rotary burr manufacturers,wholesale rotary burr,cutting tools for stone