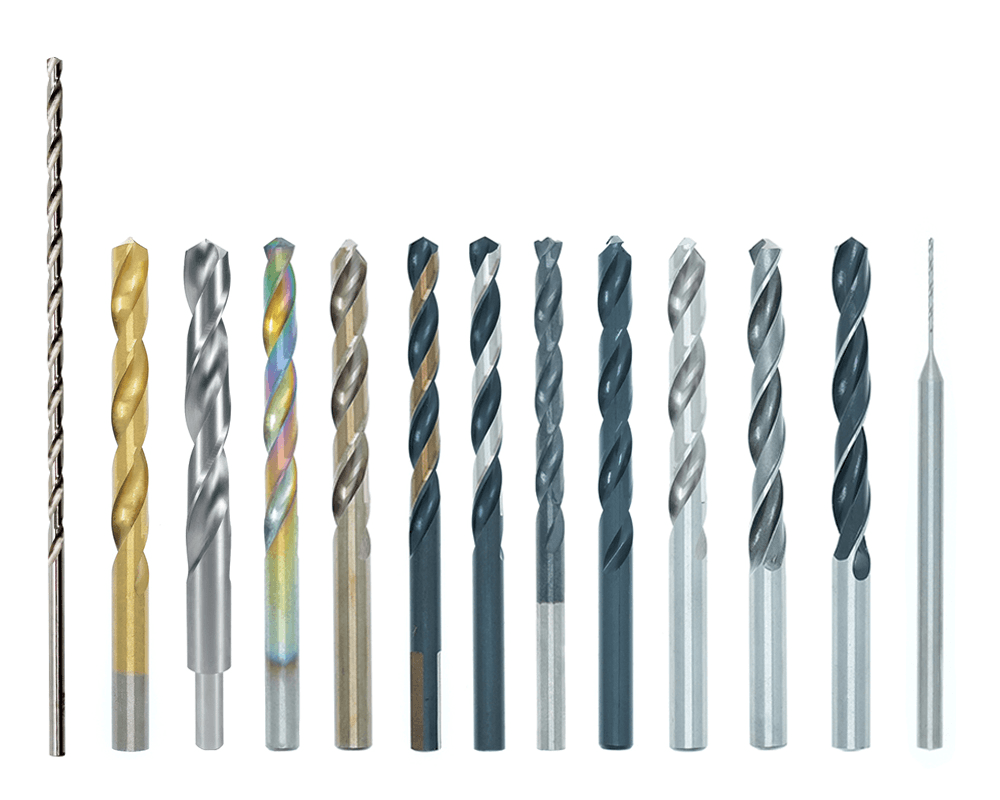

Twist drill bits have long been a staple in the industrial world, often referred to as the “jack-of-all-trades” tool due to their versatility and wide range of applications. Let’s explore why these drill bits are still considered a must-have in manufacturing, construction, and various industries.

1. The King of Materials

Wood/Plastic:

For drilling into wood and plastic, a standard HSS (High-Speed Steel) twist drill bit is the perfect tool. It works efficiently at speeds of 2000-3000 RPM, providing quick, clean holes.

Steel:

When working with steel, a cobalt twist drill bit (with a touch of cutting oil) can handle the job. Even for materials with hardness up to HRC 65, it can easily cut through without any trouble. Many twist drill bit suppliers offer cobalt drill bits specifically for hard materials like steel.

2. Cost-Effective Power

Affordable:

Standard national standard drill bits (priced as low as $1 per bit) are widely available. Their affordability allows users to perform rough drilling without the worry of excessive costs. Twist drill bit China manufacturers provide cost-effective options that are perfect for everyday use.

Low Replacement Costs:

The replacement cost is low, and it only takes 3 seconds to replace the bit, making it an excellent tool for high-volume tasks.

3. The “Hidden Potential” of Twist Drill Bits

Modifiable for Special Uses:

Grinding the top angle to 140° can turn it into a stainless steel drill bit, ideal for drilling hard metals. This versatility makes twist drill bit made in China a great option for those needing specialized drilling tools at a competitive price.

Deburring and Sharpening:

When the drill bit dulls, skilled users can use it as a reamer to fix burrs or perform fine adjustments—this old-school technique passed down by seasoned workers.

Pitfalls to Avoid

- Don’t use regular twist drill bits for hardened steel—they’ll burn out quickly. Special drill bits or techniques are required for tough materials.

- When drilling aluminum, it’s essential to sharpen the drill with a 15° point angle to prevent material build-up and improve cutting performance.

- For holes deeper than 3 times the diameter, make sure to back out the drill bit regularly to clear chips and avoid overheating.

No matter how advanced or specialized other drill bits become, the standard twist drill bit remains the go-to tool in the industrial world. Its versatility, affordability, and adaptability across various materials and tasks make it an indispensable part of any toolkit. Whether you’re sourcing from a twist drill bit supplier or looking for wholesale twist drill bits, these bits continue to deliver value and performance.

Keywords:

Twist drill bit China,twist drill bit made in China,twist drill bit supplier,wholesale twist drill bits